Release liner is one of those things that is easily forgotten. In the manufacturing process, whether it is carrying a label, sticker, tape, or another “sticky” item, the release liner is disposed of. In other words, it is considered a by-product or waste.

The thing with release liner though, is that it is much more important than you might think. It must be created specifically for your product and needs. If your release liner is not performing the way you need it to, it can cause serious problems for your manufacturing process or it can cause issues for your end-use customer and their production, whether they are applying labels to product packaging, tape to an automotive part, or even applying a bandage onto the skin of a patient.

Release liner provides a protective barrier between the adhesive and the substrate, and also ensures that the adhesive is applied evenly and correctly. Release liners consist of 3 basic components: Base Material, Coating, and Silicone. And while we could write a book on the properties, performance, and essentials of release liner, in this blog we are going to discuss coated paper liners and compare two of the most popular products; Clay Coated and Poly Coated.

As its name implies, clay-coated release liner is made from a paper base that has been coated with a layer of clay. The positives of clay-coated liners are that they have improved dimensional stability and can withstand high oven temperatures. The dimensional stability helps the sheet layflat during coating applications, which can be helpful when using a product that’s temperature or humidity sensitive. The ability to run at high temperatures means that the end-use customer can run their applications at much higher speeds. Lastly, clay-coated release liners are typically more affordable than their poly-coated counterparts.

Poly-coated release liner is also made from a paper base, but often can be made from a lower quality base paper than those that are clay-coated. This is because these liners are coated with a layer of polyethylene or polypropylene. The film coating helps to improve the moisture resistance of the paper and to make it more resistant to tearing. The film coating also provides a smoother, even texture, which can make poly-coated liners more desirable in applications where a good surface finish is important. Poly-coated release liners are typically not used in high-temperature applications, as the heat can cause the polyethylene or polypropylene coating to blister.

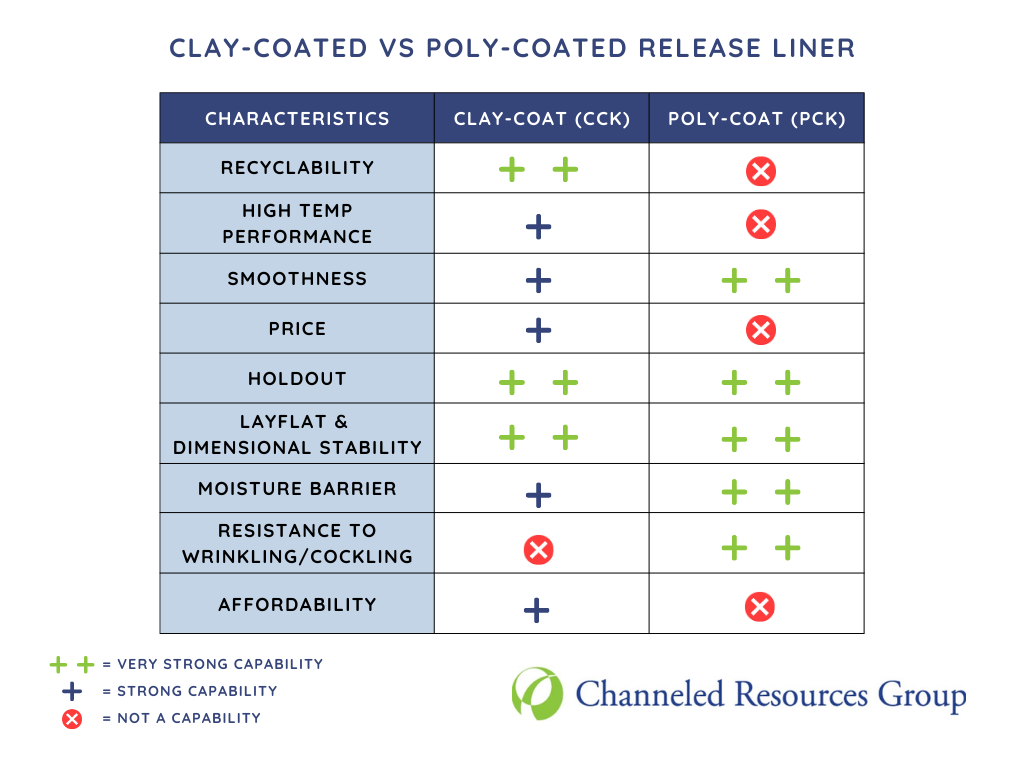

This chart compares the two liner types:

Which Release Liner Should You Choose?

The best type of release liner for a particular application will depend on the specific end-use needs. Both liners provide excellent holdout and ultra-smooth surfaces. Clay-coated release liners are a good choice for applications where high temperatures are used in the manufacturing process. Poly-coated release liners are a good choice for applications where anti-curl or moisture resistance is important.

Regardless of your end-use requirements, it is always a good idea to work closely with your release liner provider to ensure they know your specific needs and can provide you with the optimum choice.

Contact CRG’s experts to discuss what liner is best for you:

Ginnie Gandy, Release Liner Market Manager

ggandy@channeledresources.com

End-of-Life Considerations

When it comes to release liner, there is another thing to consider. As a by-product or waste item, it is important to think about what happens to all the release liner after it serves its purpose.

As an industry pioneer and longstanding champion of sustainability in the label and liner industries, what happens to release liner is always top of mind for CRG. One answer, unfortunately, is that some release liner inevitably winds up in landfills.

Poly-coated liners are, in essence, extruded plastic on top of a paper sheet, which prevents them from being recycled in a standard paper recycling stream. On the other hand, because clay is incorporated into the paper sheet during the paper manufacturing process, the clay-coated release liner is recyclable in more standard paper recycling streams.

There have been recent advancements in best sustainability practices and there are facilities throughout the U.S. where non-recyclable by-products are being used for waste-to-energy initiatives. You can view a map of recycling facility locations here and a map of non-landfill options for by-products here.

Our experts are happy to discuss your specific release liner needs, including options for your release liner waste. We are keenly aware that companies are constantly looking for more effective ways to improve their sustainability practices and to enhance the ways that they are telling their sustainability stories.

Contact Ginnie Gandy to learn more: ggandy@channeledresources.com

Read more about our sustainability initiatives here.