Why fix it if it isn’t broken? Unfortunately, this phrase is much too common in the double-booked, over-scheduled, too-busy life we all seem to find ourselves in these days. The problem with allowing yourself to stick with the status quo is you could be sacrificing your productivity, missing out on a sustainability win, and worst of all, leaving money on the table.

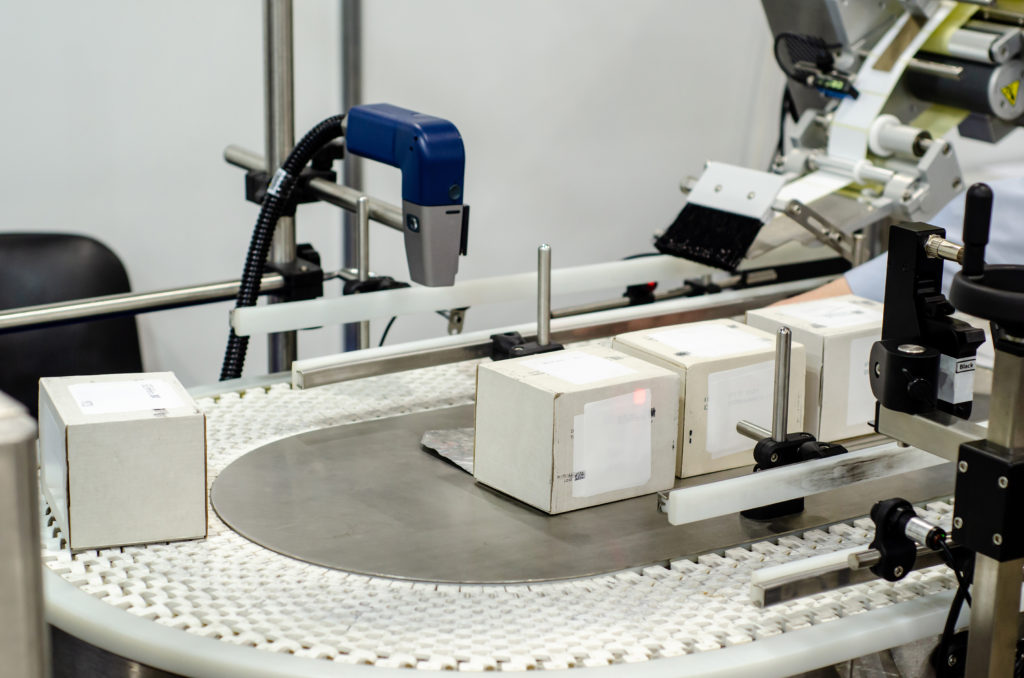

While you may use die-cut blank labels with paper liner because it works fine and frankly because you’ve just always used it, now might be the time to take a look at whether a switch to a die-cut blank label with a PET liner might be right for your production needs.

CRG can now offer you both paper liner and PET liner options for your die-cut blank label needs. We aren’t saying that you should definitely switch, but we should at least have a conversation to determine which is the best option for your individual production needs.

PET liners definitely come with some distinct advantages. More labels per roll mean fewer roll changes and downtime. PET has a smoother release and due to the increased durability of films vs. papers, you’ll see fewer liner breaks keeping your production up and running.

Often times paper is touted as a more sustainable option than film, but when you’re talking about the liner, you are talking about a waste product. PET liners are more easily recycled than paper liners, making them a sustainable win for your plant.

Change is hard. We understand that everyone is busy and it can often be difficult to take time to make changes in your production environment. Making the change from a die-cut blank label with a paper liner to one with a PET liner is actually pretty seamless! Your label applicator only needs a simple recalibration and you will be right back up and running… more efficiently than ever!

Learn more about CRG’s die-cut blank labels with PET liners here or reach out to speak with one of our experts. We can help you determine what’s the best fit for your specific needs.